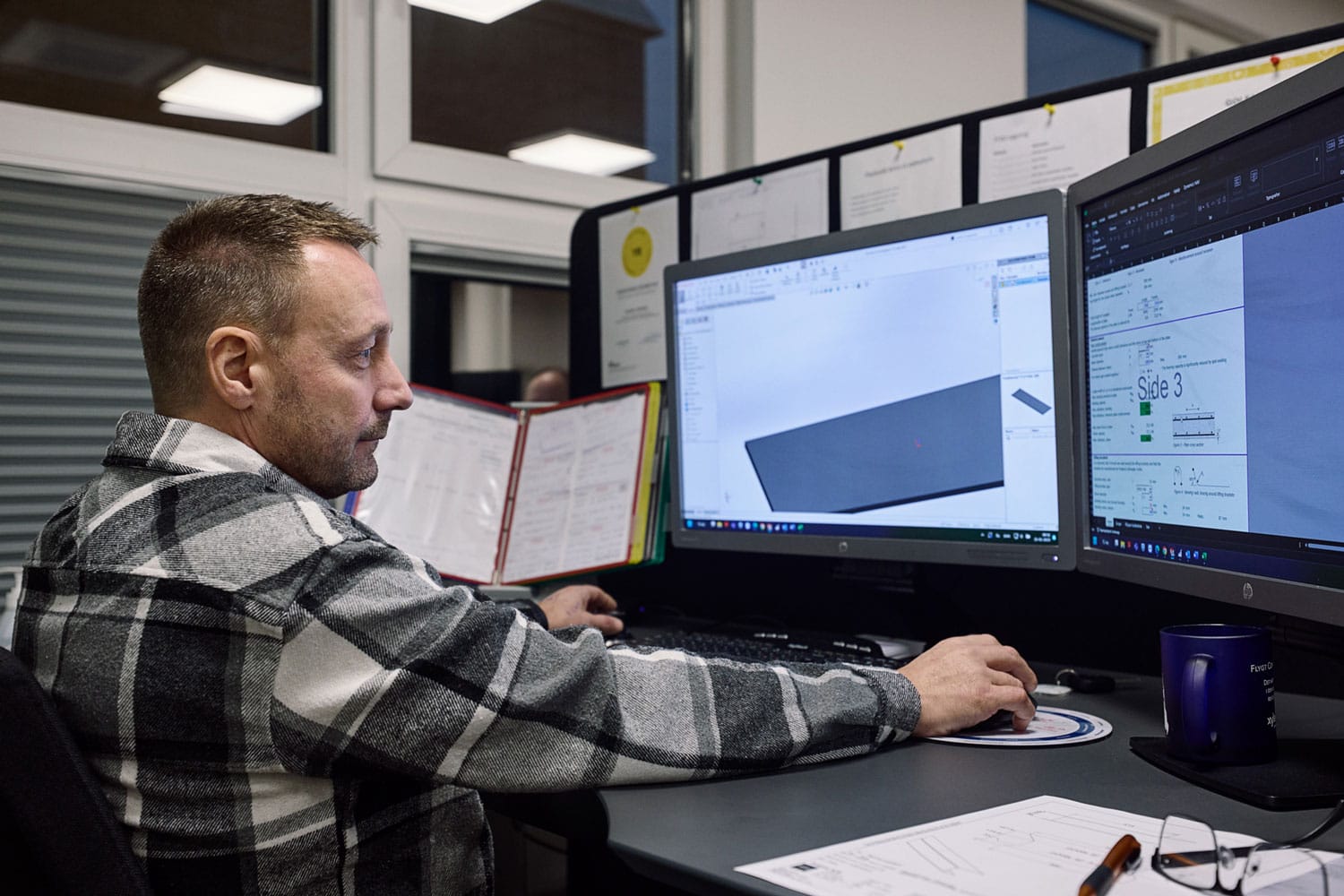

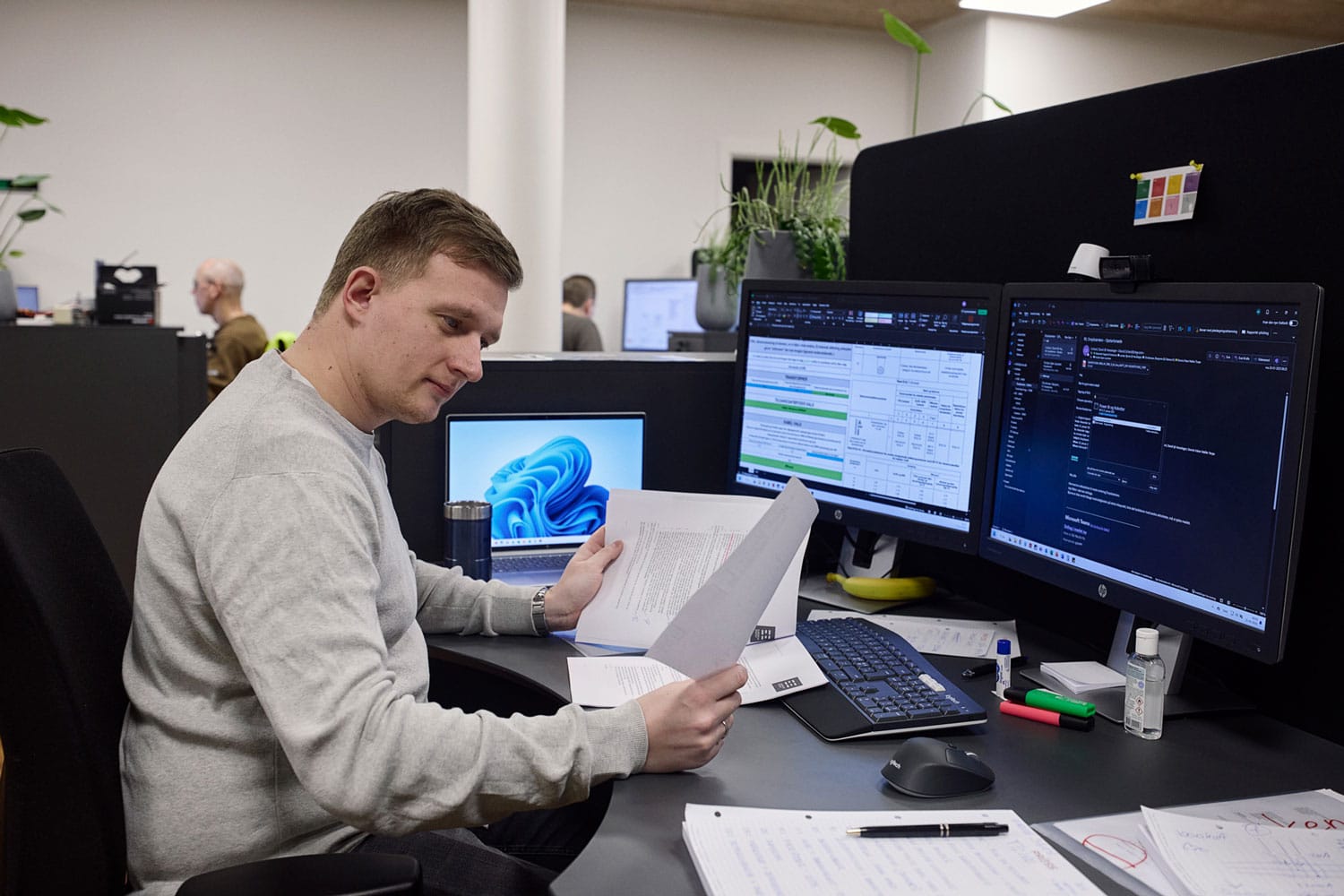

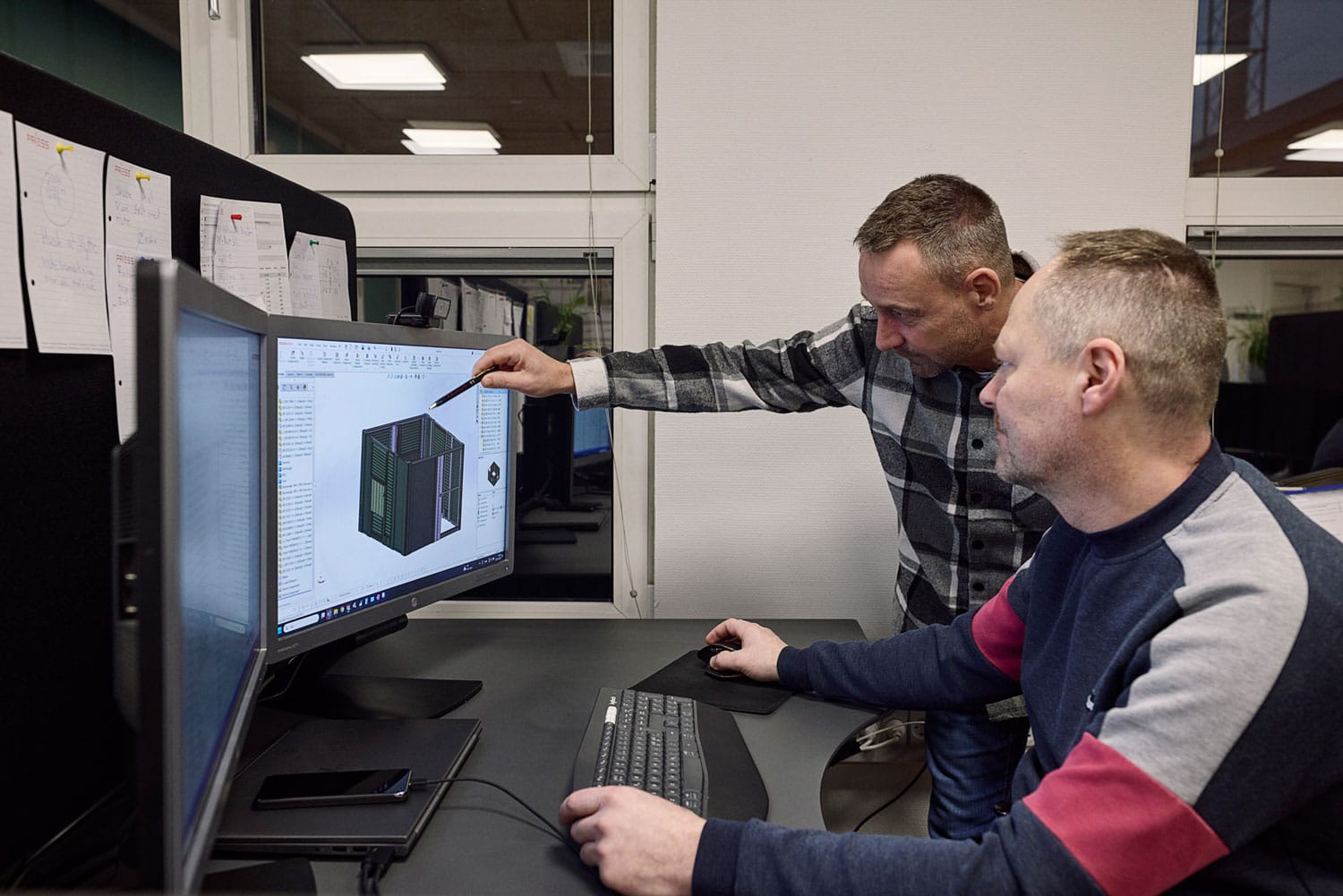

Our Process – Every Step From Design to Delivery

At Priess District Heating, we take responsibility for the entire lifecycle of the project – from the initial design to handover and operation. Our approach ensures high quality, predictable delivery, and a solution that is fully integrated into the customer’s technical and operational framework.

We handle every part of the project lifecycle – from the first design sketches to operational installation. At Priess, every solution we design is modelled in 3D, tested and CE-marked, and we document everything through a comprehensive FAT and handover process.